Автоматическая поршневая наполнительная машина NP-VF

Это автоматическая поршневая фасовочная машина с сервоприводом и несколькими наполнительными головками, предназначенная для удовлетворения различных требований к производительности.

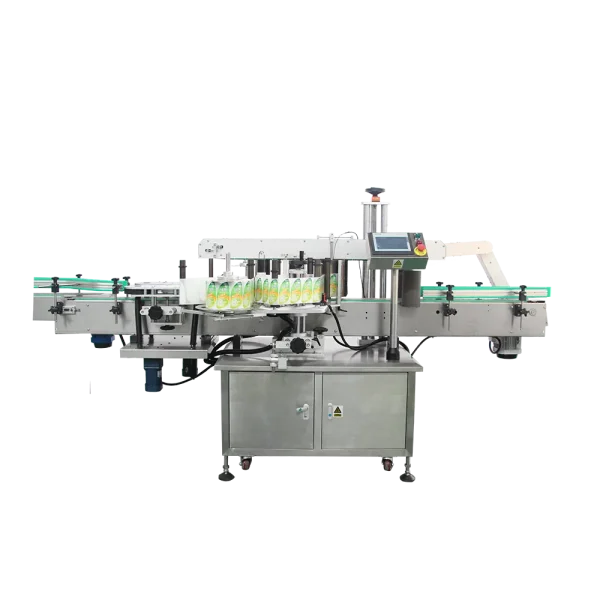

Автоматическая многоголовая вертикальная поршневая фасовочная машина в линию

Автоматическая поршневая наполнительная машина NP-VF

Поршневая фасовочная машина в линию NP-VF приводится в движение главным серводвигателем или отдельными серводвигателями для каждого поршня. Это основной продукт компании NPack, разработанный за десять лет, способный фасовать высоковязкие и сильно пенящиеся жидкости в пищевой, химической и косметической промышленности. Для автоматических систем объемного дозирования NP-VF является одним из лучших вариантов благодаря стабильной рабочей технологии, высокой эффективности и низким инвестициям.

- Материал конструкции машины — нержавеющая сталь марки 304, с сертификатом качества материала.

- Поршни и дозирующая головка изготовлены из нержавеющей стали 316L с сертификатом на материал.

- Прокладки поршня изготавливаются из некоррозионного материала в зависимости от жидких продуктов.

- Электрическая установка и ЦПУ спроектированы и изготовлены с водонепроницаемым исполнением.

- Пневматическая система адаптирована с использованием SMC или Festo в качестве основных компонентов.

- Человеко-машинный интерфейс (HMI) установлен на стороне выгрузки продукта.

- Оснащена как минимум 3 кнопками аварийной остановки: одна возле сенсорного экрана, одна со стороны подачи пустой тары и одна на задней стороне машины.

- Процессор и человеко-машинный интерфейс (HMI) доступны в европейских, японских и китайских брендах.

- Электрические компоненты — Schneider

- Идентификация каждого кабеля с использованием однолинейной электрической схемы для всей электрической установки.

- Шарикоподшипники и уплотнения от SKF и ведущих китайских брендов.

- Сервоприводные погружные наполнительные головки для точного дозирования и наполнения жидкостей.

- Пневматические отсечные и каплезащитные наполнительные насадки

- Поддон для сбора капель является стандартной опцией.

Совместимые Запасные Части и Расходные Материалы

Для обеспечения бесперебойной работы и длительного срока службы поршневой фасовочной машины NP-VF важно использовать высококачественные совместимые запасные части и расходные материалы. Система спроектирована для работы с широкодоступными вариантами от проверенных брендов, таких как SMC, Festo, Schneider, SKF, а также ведущих китайских производителей.

Рекомендуемые типы запасных частей и расходных материалов включают:

Полиуретановые (PU) пневматические трубки

Доступны в различных внутренних и внешних диаметрах (например, 6мм x 4мм, 8мм x 5мм, 10мм x 6.5мм), в синем и черном цветах, чтобы соответствовать различным требованиям к подаче воздуха.Уплотнительные кольца FKM 75 (витон)

Эти уплотнения, предлагаемые в нескольких размерах, обеспечивают высокую химическую стойкость и долговечность для надежной работы поршня и дозирующей головки.Электромагнитные клапаны

Высокопроизводительные клапаны обеспечивают точное пневматическое срабатывание в системе для стабильных циклов наполнения.Шарикоподшипники и уплотнения

Компоненты от признанных производителей обеспечивают плавное механическое движение и предотвращают загрязнение.

При выборе запасных частей всегда сверяйте технические характеристики—такие как размеры и совместимость материалов—с техническими параметрами системы. Это гарантирует постоянную эффективность, безопасность и точность вашей поршневой фасовочной машины, независимо от того, разливаете ли вы лосьоны или дозируете мед. При правильном обслуживании и использовании оригинальных расходных материалов ваше оборудование остается оптимизированным для ежедневной работы, сокращая незапланированные простои и повышая производительность.

Интегрированная конвейерная система: Проектирование и эксплуатация

Интегрированная конвейерная система спроектирована для обеспечения плавной и надежной транспортировки емкостей на протяжении всего процесса наполнения. Конвейер выполнен с прочной плоской цепью шириной 100 мм (3,94 дюйма) и обеспечивает стабильное движение бутылок различных форм и размеров. Стабильность емкости дополнительно улучшена за счет механизма фиксации горлышка бутылки, сводящего к минимуму риск опрокидывания или смещения во время наполнения.

Регулировка высоты выполняется просто, что обеспечивает плавную интеграцию в существующие производственные линии и эргономическую совместимость. Скорость конвейера полностью регулируется в диапазоне от 0 до 18 метров в минуту, позволяя операторам согласовывать производительность с различной вязкостью продукта и требованиями к наполнению.

Функция «нет бутылки — нет наполнения» гарантирует, что продукт подается только при правильном расположении контейнеров, что оптимизирует использование продукта и безопасность эксплуатации. Быстросъемные соединения и продуманное размещение компонентов упрощают плановое техническое обслуживание, сокращают время простоя и обеспечивают эффективную работу линии.

Автоматическая система обнаружения бутылок

Для обеспечения точной и эффективной работы фасовочная машина использует фотоэлектрические датчики для плавного управления каждым циклом дозирования. Когда контейнеры перемещаются в заданную зону наполнения, эти датчики оперативно распознают их присутствие. Как только бутылка правильно установлена, система автоматически запускает следующий цикл наполнения, сводя к минимуму ошибки и максимизируя производительность без ручного вмешательства.

Эта интеллектуальная система обнаружения не только помогает поддерживать стабильность продукта, но и обеспечивает высокоскоростное бесперебойное производство, что делает NP-VF подходящей для самых разных производственных условий.

NP-VF - это превосходное поршневое фасовочное оборудование, разработанное для дозирования вязких жидкостей в различных отраслях. Оно демонстрирует высокую эффективность в сферах бытовой химии и косметики для дозирования таких продуктов, как лосьоны для тела, косметические кремы, эмульсии, гели, жидкое мыло, сыворотки, шампуни и моющие средства. Кроме того, оно получило популярность для фасовки пищевых жидкостей и соусов, включая томатный соус, кетчуп, мед, соевый соус и пищевые масла. Универсальность NP-VF делает его ценным активом для точного и эффективного дозирования в широком спектре применений.

| Имя | Спецификация |

|---|---|

| Наполнительные насадки | 2-20 |

| Производительность/Ёмкость | От 10 до 150 ударов в минуту |

| Мощность | 1,5 кВт - 3 кВт, 220/380 В перем. тока |

| Точность | ±3 мл на основе 1000 мл |

| Привод | Серводвигатель |

| Объем наполнения | от 100 мл до 5000 мл |

| HMI | Немецкий или китайский бренд |

Weitere Produkte oder Dienstleistungen

Sia che vogliate potenziare la vostra linea di produzione esistente o iniziare un nuovo progetto, abbiamo le soluzioni giuste per voi. Le nostre macchine sono dotate di funzionalità avanzate per mantenere la qualità del prodotto e ridurre gli sprechi. Inoltre, il nostro team esperto è sempre a disposizione per fornire una guida e un supporto specializzati.