The main construction material is 304SS (a quality certificate can be provided); The piston material is ceramic, 316SS, or titanium, and the top liquid polished tank is made of 304SS or 316L stainless steel, which can be selected; the filling nozzle can be selected according to the need; The piston gasket is made of non-corrosive materials such as Teflon.

Using durable materials and components, as well as waterproof control cabinets and boxes, ensures durability and reliability. The pneumatic components use Airtac and SMC, with Festo available as an alternative supplier.

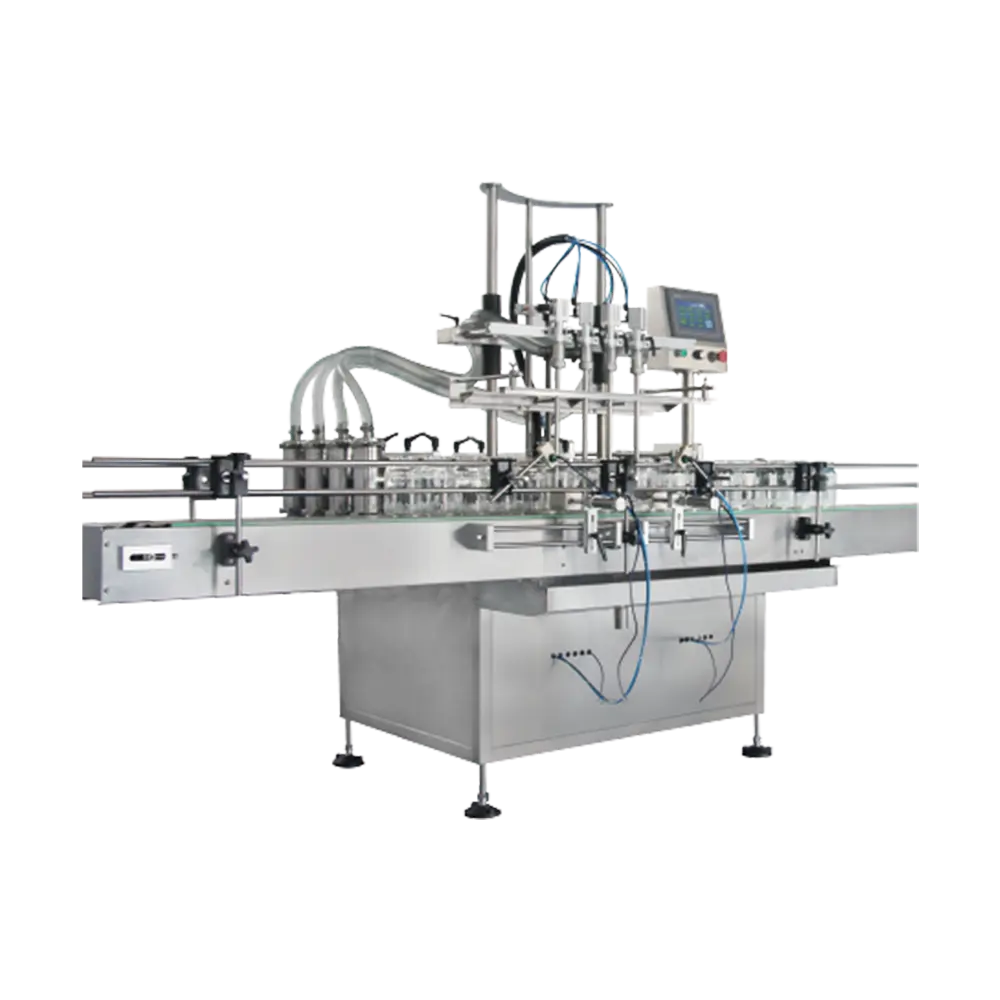

The Siemens HMI is placed for the operator’s convenience on the front side of the machine. The entire machine is equipped with 3 emergency stop buttons, one of which is located below the touch screen, one on the bottle feed side, and the other on the back of the machine.

Some main components come from top brands such as Siemens, Panasonic, and Schneider, ensuring advanced technology and reliability. Electrical components are specifically sourced from the trusted brand Schneider.

The organized electrical installation enables each cable to be identified and recorded by a single wire electrical diagram that can cover the entire system. To ensure optimum performance, ball bearings and seals are sourced from SKF and other top Chinese brands.

Equipped with a servo-driven diving filling head, it can accurately dive and easily adjust containers of different heights. Use pneumatic cut off or anti-drip filling nozzle. Drip trays are standard to further ensure clean and efficient operation

The operation of automatic piston filling machines, such as the filling machine provided by Shanghai Npack, is both intuitive and efficient. This filling machine shares common characteristics with other filling machines, integrating basic components such as pistons and advanced servo drive and control systems, including PLC (Programmable Logic Controller), frequency converter, and motor.

The key of the piston filling machine is the accuracy and volumetric filling mechanism is the key. This is also the main reason why people are willing to use piston filling machines. Pistons and cylinders are key components in this process. The working principle of this system is direct stroke movement, which makes it easy to accurately measure and dispense liquid into the container.

At the beginning of the operation, first pull the piston to allow the liquid to enter the cylinder. Subsequently, push the piston to inject the accurately measured liquid into the bottle. This systematic push-pull movement an ensure a reliable and efficient liquid filling process.

Here we are listing some of the popular application industries for piston filling machines:

- Food and Beverage: this liquid filling machine is perfect for thick food items like sauces, jams, honey, and condiments, as well as for fruit juices or water. Apart from the aforementioned items, the piston filling machine is suitable for various food and drink purposes, including dairy products, salad dressings, and others. They are proficient at filling tasks with precision and speed, and can fulfill various packaging requirements effectively.

- Cosmetics and Personal Care products: In the cosmetics packaging process, piston fillers are used for accurately dosing and filling creams, lotions, gels, and other skincare cosmetics liquid.

- Pharmaceuticals: Piston filling machines are also popular application in the pharmaceuticals ,for filling syrups, creams, pastes, and other medicinal preparations, the most often using piston material is the ceramic piston pump, GMP and FDA standard.

- Chemicals: non corrosive chemical liquids , such as detergents, shampoo,solvents, and lubricants, piston fillers can effectively handle both harsh and delicate chemical viscosities while ensuring that containers are filled to the precise level required.

- Household Products:Similarly, these filling machines can also be used to fill non-edible household products, such as cleaning products, dishwashing liquid, and other household or industrial chemicals.

- Paints and Coatings: Piston pumps are used to spot fill products with different types of paint and coatings, which is common and may be inconsistent for filling thick, viscous products.