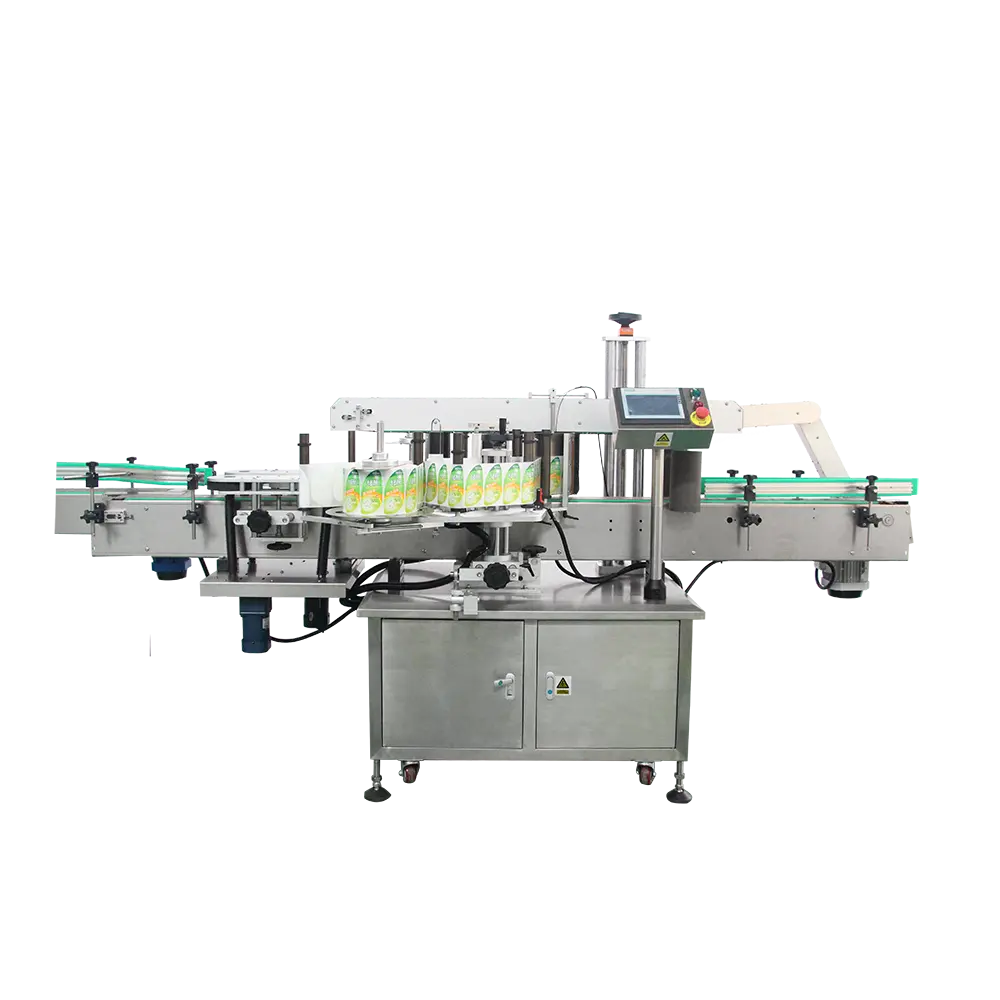

NP-TS Front Back Labeling Machine

NP-TS Front Back Labeling Machine Inline High Speed Labeler

Front Back Labeling Machine

NP-TS labeling applicator is adept at both double sides and single side sticker labeling, making it an automatic, self-adhesive labeling powerhouse suitable for various bottle shapes, including flat, square, and round bottles. Its broad applicability spans numerous fields such as food, cosmetics, medicine, and pesticides, positioning it as a vital equipment for businesses aiming to enhance their labeling efficiency and accuracy with a machine capable of handling both double-sided and single-sided sticker applications.

Designed to accommodate a wide variety of packaging needs, the machine can apply one, two, or even more labels to the front and/or back of containers. Whether you’re working with elliptical, rectangular, or even uniquely-shaped bottles and jars—be they plastic, glass, or metal—this solution is engineered for versatility, making it ideal for diverse industry requirements, from food and beverage to pharmaceuticals, household chemicals, and personal

The Front Back Labeling Machine boasts a comprehensive set of features designed for optimal performance in labeling applications:

- Premium Construction: Crafted entirely from 304/316 grade stainless steel, this machine adheres to GMP standards, ensuring durability and compliance with health and safety regulations.

- Advanced Control System: Equipped with a color Siemens Smart HMI for control and operation, it offers a bilingual operation interface in both Chinese and English, with other languages customizable as needed.

- High-Precision Labeling: Panasonic servo motor-driven labeling heads feature automatic bottle separation and correction mechanisms, enhancing labeling accuracy and stability, ensuring labels are precisely applied every time.

- Reliable Automation: Powered by a servo motor and controlled by PLC, it guarantees labeling that is not only accurate but also stable, reliable, and efficient—catering to high-speed production demands.

- Versatile Adjustment: With adjustable labeling height and angle, this machine is versatile enough to handle a variety of container shapes, including round, square, and flat bottles, making it suitable for a wide range of labeling tasks.

- Flexible Product Compatibility: Capable of labeling containers of different materials—whether plastic, glass, or metal—across multiple sizes and designs.

These features collectively make the Front Back Labeling Machine an indispensable asset for industries requiring efficient and precise labeling solutions, such as food, cosmetics, and pharmaceuticals.

- Ribbon Coding Machine: Can print production date and batch number.

- Industrial Zebra Engine: For transcoding printing, docking with system software, and integrated real-time printing functionality.

- Transparent Label Detection: Compatible with all label types, including gilded, transparent, paper, or composite S material labels. No need to replace sensors when switching label types. Transparent label detection on the lower lining of transparent labels.

- Visual Inspection Removal: Detects label presence and verifies printed information, batch numbers, and content correctness.

- Heat Transfer Intelligent Coding Machine: Prints QR codes, barcodes, production dates, batch numbers, and more on label paper, enabling product traceability and anti-counterfeiting measures.

| Technical Parameters | |||

| Speed | 60-350pcs/min (Depending on label length and bottle thickness) | ||

| Height | 30-350mm | ||

| Thickness of Object | 20-120mm | ||

| Height of Label | 15-140mm | ||

| Length of Label | 25-300mm | ||

| Label Roller Inside Diameter | 76mm | ||

| Label Roller Outside Diameter | 420mm | ||

| Accuracy | ±1mm | ||

| Power | 220V 50/60HZ 3.5KW Single-phase | ||

| Air Consumption | 5Kg/cm^2 | ||

| Dimension | 2800(L)×1650(W)×1500(H)mm | ||

| Weight | 450Kg | ||

The double sides sticker labeling machine is a state-of-the-art solution designed to efficiently apply self-adhesive stickers on both sides of various containers, such as bottles, jars, and cartons. This machine is engineered for precision and flexibility, accommodating a wide range of container shapes and sizes, making it ideal for industries including food and beverage, cosmetics, pharmaceuticals, and household chemicals.

Other Products Or Services

Whether you’re looking to enhance your existing production line or starting a new project, we have the right solutions for you. Our machines are equipped with advanced features to maintain product quality and minimize waste. Additionally, our knowledgeable team is always available to provide expert guidance and support.