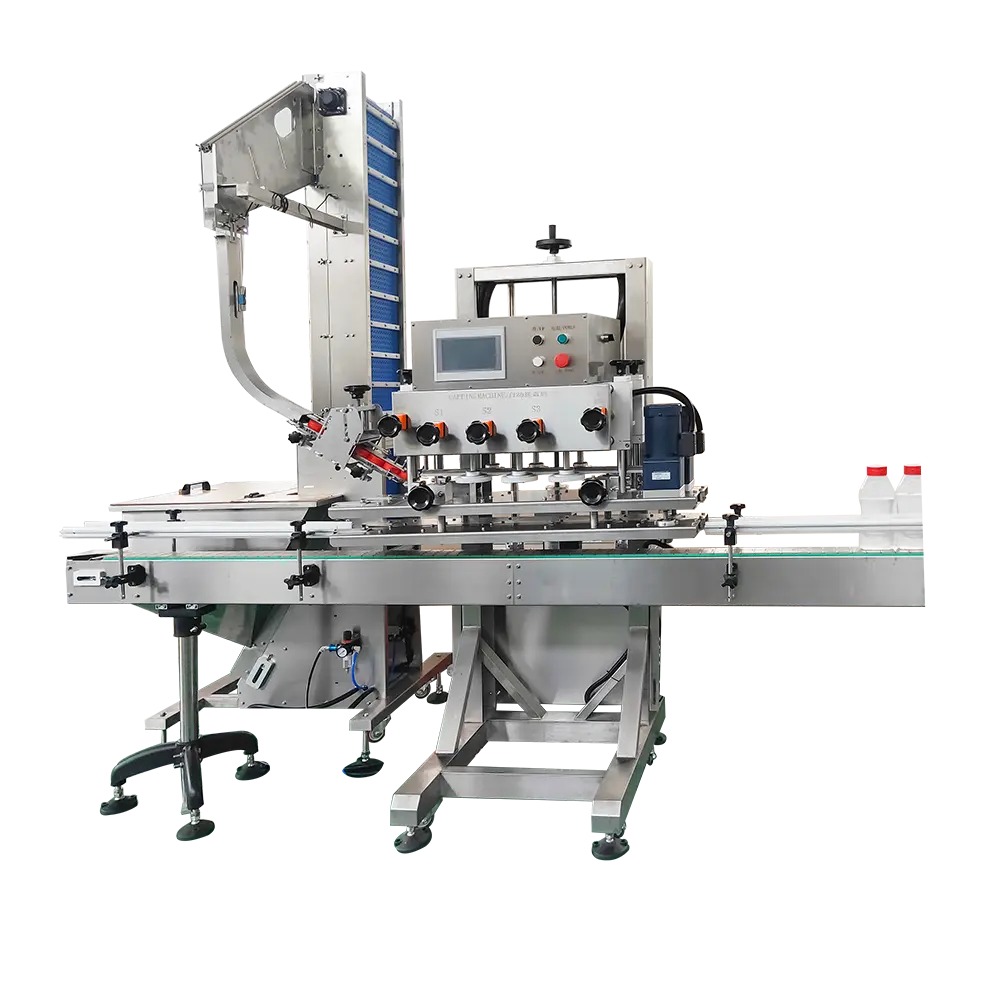

NP-LC Spindle Capping Machine

Six spindle wheels screw capping system.

Flexible 6 wheels Spindle Capper CE certified Equipments

NP-LC Spindle Capping Machine

The Shanghai Npack NP-LC Automatic Spindle Capping Machine is a flexible bottle screw capping machine and an essential tool for improving efficiency in the bottling and sealing process. With its precision design and flexibility, this machine offers unparalleled versatility when it comes to handling various cap types and sizes.In industries such as healthcare, beauty, food, and beverages, where product quality and safety are of utmost importance, this capping machine proves to be indispensable. It effortlessly manages different caps including screw caps, flip-top caps, spray caps, dropper caps, metal caps, and twist-off caps. Investing in the Shanghai Npack NP-LC Automatic Spindle Capping Machine is a wise choice for businesses looking to streamline their bottling processes while ensuring superior quality control. With its ability to handle a wide range of cap types and sizes effortlessly combined with its reliability and durability features makes it an ideal solution for any industry requiring efficient bottle sealing operations.

- The machine’s six main spindle wheels not only ensure consistency and accuracy in cap application but also efficiently seal and maintain the integrity of various products. This feature is particularly suitable for industries requiring precise packaging, such as pharmaceutical or food production.

- The machine is equipped with two sets of mechanical clutches, which provide excellent control over torque application during the capping process. This ensures that each cap is precisely and securely tightened without compromising the integrity of the cap or the product inside. For users seeking higher performance and ease of operation, a servo motor drive system is available as an optional feature.

- The setup process for this machine is made simple through easy-to-use front knob adjustments. These adjustments allow for quick and accurate changes to accommodate different cap sizes and types, making it effortless to transition between different products on a production line.

- To enhance operational efficiency and reduce noise levels, this machine features a sophisticated non-vibratory feeder system. This system provides a steady supply of caps to the capping mechanism while minimizing disruptions caused by vibrations. Additionally, depending on cap size, the feeder has a capacity to store up to 800pcs at one time (depending on different sizes).

- Offering exceptional flexibility in packaging needs, this machine is capable of handling caps ranging from 8 mm to 120 mm in size. It can accommodate various types including 400 caps (commonly used for beverages), 410 caps (often found in cosmetics), as well as CRC caps (child-resistant closures) commonly used in pharmaceuticals.

- Designed for fast and easy changeovers between different products or packaging requirements, this machine significantly reduces downtime during production processes. By streamlining changeover procedures, more time can be dedicated to actual manufacturing activities.

NPACK NP-LC Six-Spindle Capping Machine is engineered to fulfill the rigorous requirements of contemporary packaging lines. Featuring a durable build and cutting-edge design, this machine presents an optimal solution for enterprises aiming to enhance their bottling and sealing processes. It is exceptionally well-suited for a variety of sectors, including pharmaceuticals, cosmetics, food, and beverages, offering unparalleled versatility and dependability. This machine is tailored to support businesses in achieving efficient and reliable capping operations, ensuring product integrity and quality.

- The principle we follow is ‘one motor per capping wheel’ to ensure the machine operates reliably with consistent torque even during prolonged usage. This new design guarantees that each capping wheel functions on its own, minimizing the chance of mechanical malfunctions or interruptions while capping. Having this dependable system installed, manufacturers can rest assured that their production line will operate smoothly and effectively.

- Variable clamping belts increase the machine’s ability to adjust to different packaging needs by capping bottles of varying heights and shapes. Our machine can handle both tall bottles and irregularly shaped containers with ease. The flexible clamping belts provide a firm hold on every bottle while capping, avoiding any slipping or misalignment that could impact the quality of the product.

- An optional cap guiding system can be integrated, making the machine compatible with pump caps and expanding its versatility. By incorporating a cap guiding system into our machine design, we offer manufacturers greater flexibility in their packaging options. Pump caps are commonly used for products such as lotions or creams, and our machine’s compatibility with these types of caps allows for seamless integration into diverse production lines.

- Equipped with a convenient construction adjustment system that includes a precise ruler and counter, this feature allows for easy and accurate adjustments. Our goal is to simplify setup procedures for operators while ensuring precision in every adjustment made. The inclusion of a precise ruler and counter enables operators to make quick measurements and track changes accurately without relying on guesswork.

- The machine’s mainframe is designed with efficiency and convenience in mind. Equipped with a powerful motor, it effortlessly lifts and lowers to accommodate different bottle sizes, ensuring seamless adjustments during the production process. The adjustable two-belt height feature further enhances its versatility by allowing for easy adaptation to various bottle dimensions.

- To ensure the utmost protection of caps, the capping wheels are thoughtfully crafted from a soft material. This not only prevents any potential damage to the caps but also guarantees their integrity throughout the packaging process. Additionally, an advanced servo system complements these wheels, providing precise control and enhancing overall performance.

- With these advancements at hand, manufacturers can confidently rely on this machine to efficiently handle bottles of all shapes and sizes without sacrificing quality or productivity levels.

Using Spindle Cappers as Cap Tighteners

Spindle capping machines aren’t just built for fully automated lines—they also shine when tasked as reliable tighteners for hand-placed or trigger-style caps. For manufacturers handling manually positioned caps, these machines offer a significant advantage: once an operator places a cap onto a bottle by hand, the spindle capper efficiently secures and tightens the cap to consistent torque specifications.

This approach is especially useful for unique cap types, like trigger sprayers or flip-top lids, often found in home care, cosmetics, or specialty food products. When operators manually set these sometimes irregular caps in place, the spindle capper engages, steadily tightening each one without overtightening or stripping threads.

Manual placement, automated torque application: Operators initiate the capping process, while the machine ensures each cap meets quality requirements.

Adaptability for various cap styles: Whether you’re working with standard screw-on lids or more complex trigger-style caps, the spindle capping mechanism accommodates a wide range of designs.

Seamless upgrades: Should production needs expand, these machines can be further automated by integrating sorting or feeding systems—transitioning from a supportive role in manual lines to a fully automated capping solution.

By bridging the gap between manual processes and high-speed automation, spindle cappers help businesses maintain both flexibility and consistency on the packaging line.

Machine Characteristic

| NAME MODEL | NP-LC Automatic linear spindle capping machine |

| Capacity | 0~200b/m(subject to bottles and cap size) |

| Bottle and cap diameter | Φ10~120 subject to samples |

| Bottle Height | 40~380mm |

| Spindle capping machine dimension | L1060*W896*H1620mm |

| Voltage | AC 220V 50Hz |

| Power | 1600W |

| Weight | 500kg |

| Cap Feed system | Elevator feeder |

| Dimension | L880×W1000×H2600mm |

Cap Feeding Systems

Integrate elevator-style cap sorters or vibratory bowls such as Cap sort or Cap Feeder. These automated devices efficiently orient and deliver caps to the capping machine, reducing manual labor and increasing throughput.

Vision Inspection Systems:

Install cameras or vision inspection units from Cognex or Keyence to verify cap placement, height, and seal integrity right on the line, enabling on-the-fly quality assurance.

Reject and Ejection Devices:

Keep your production line moving smoothly by adding pneumatic reject stations that remove improperly capped bottles without interrupting the flow.

Control Panel Features:

we adapt with famous brand of the HMI, such as Siemens for a option and MCGS HMI as a lower cost budget.All the components we choosed are according to the rules of high quality, working stable, easy to find and fast service and maintaining.

- 5 pcs of Danfoss frequency converters used in one machine for flexible control

- 9 motors used in one for easy adjustment

- Each wheel drives one spindle wheel

- Motor drives the whole spindle wheels height up and down

Other Products Or Services

Whether you’re looking to enhance your existing production line or starting a new project, we have the right solutions for you. Our machines are equipped with advanced features to maintain product quality and minimize waste. Additionally, our knowledgeable team is always available to provide expert guidance and support.