Smart Servo Robot labeling system

Labeling Machines

Our expertise in manufacturing all types of sticker labeling machines

Industrial Labeling Machines and Applicator

Shanghai Npack’s labeling machines are designed to efficiently affix preprinted labels, including sticker labels and OPP labeling, onto products, individual packages, cartons, cases, containers, and pallet loads. These machines play a pivotal role in product identification and traceability, as well as in promoting the manufacturer’s brand image. The versatility of these machines allows for the application of labels ranging from simple black-and-white barcodes or 1D/2D codes, crucial for identification purposes, to elaborate, multicolored product labels that effectively showcase the brand’s identity, thereby capturing consumer attention and enhancing brand recognition.

Automatic Labeling Machines Selection

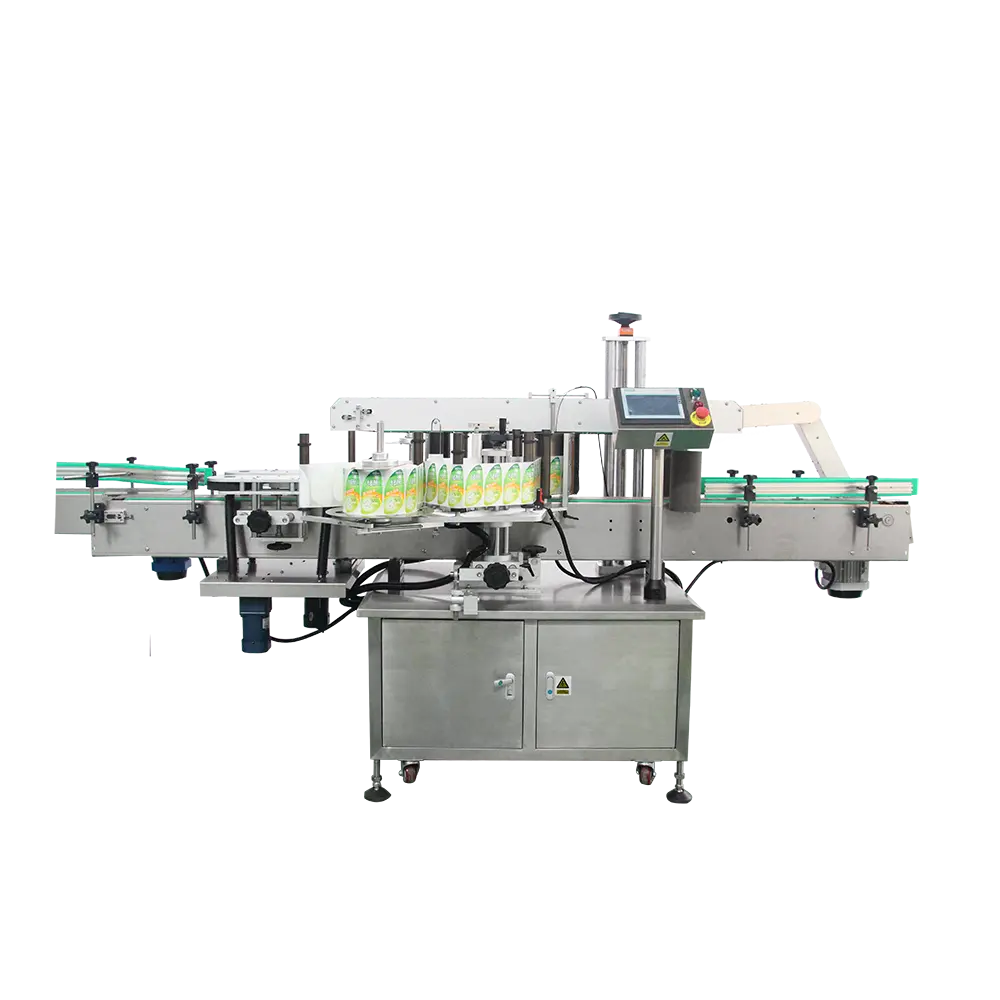

Labeling machines, also known as labelers or labeling applicators, are key components in the field of packaging equipment. These industrial tools are essential for affixing labels to the surfaces of various products, packages, or containers, including bottles, boxes, pouches, and cartons. Applications of these machines can vary widely; they are capable of applying labels on the body of a product, on one or two sides, as well as on the front and back, top, and even the corners, demonstrating their versatility and crucial role in product identification and branding.

Self adhesive Labeling machines

we also can this type of label applicator as sticker labeling machines, it is an automatic pressure-sensitive labeling machine delivers consistent and accurate labeling capabilities, enhancing productivity with its high-efficiency operation..

NP-HGL hot melt glue labeling machine

Hot melt glue labeling machine offers precision in applying (OPP/BOPP) labels to bottles, cans, and barrels, making it a key player in the automatic labeling sector.With its advanced PLC control, imported servo motors, and a positioning module, it ensures fast, accurate labeling for beverages and food industries.

NP-GL Cold Glue Labeling Machine

The NP-GL automatic cold glue labeling machine, often referred to as the wet glue labeling machine, it is application for paper labels and paste glue on labels, then sticking on bottles.It stands as a dedicated inline industrial label applicator crafted for the precise application of bottle labels

NP-LS Automatic Shrink Sleeve Label Machine

It is used in the packaging and labeling process of various products, and is suitable for round bottles, flat bottles, square bottles, curved bottles, cups and other products in light industrial industries such as food and beverage, medical, and daily chemicals.